MATERIAL: Concrete

This project represents a fusion of traditional ceramic techniques and cutting-edge digital fabrication, by integrating 3D-printed clay into the precast concrete design. As part of the course Introduction to Novel Precast Precedents, which explores the intersection of architecture, technology, and materiality. The final product, with a unique combination of fired clay pieces, is designed to be broken out of the panel, and glazed clay elements left embedded within it.

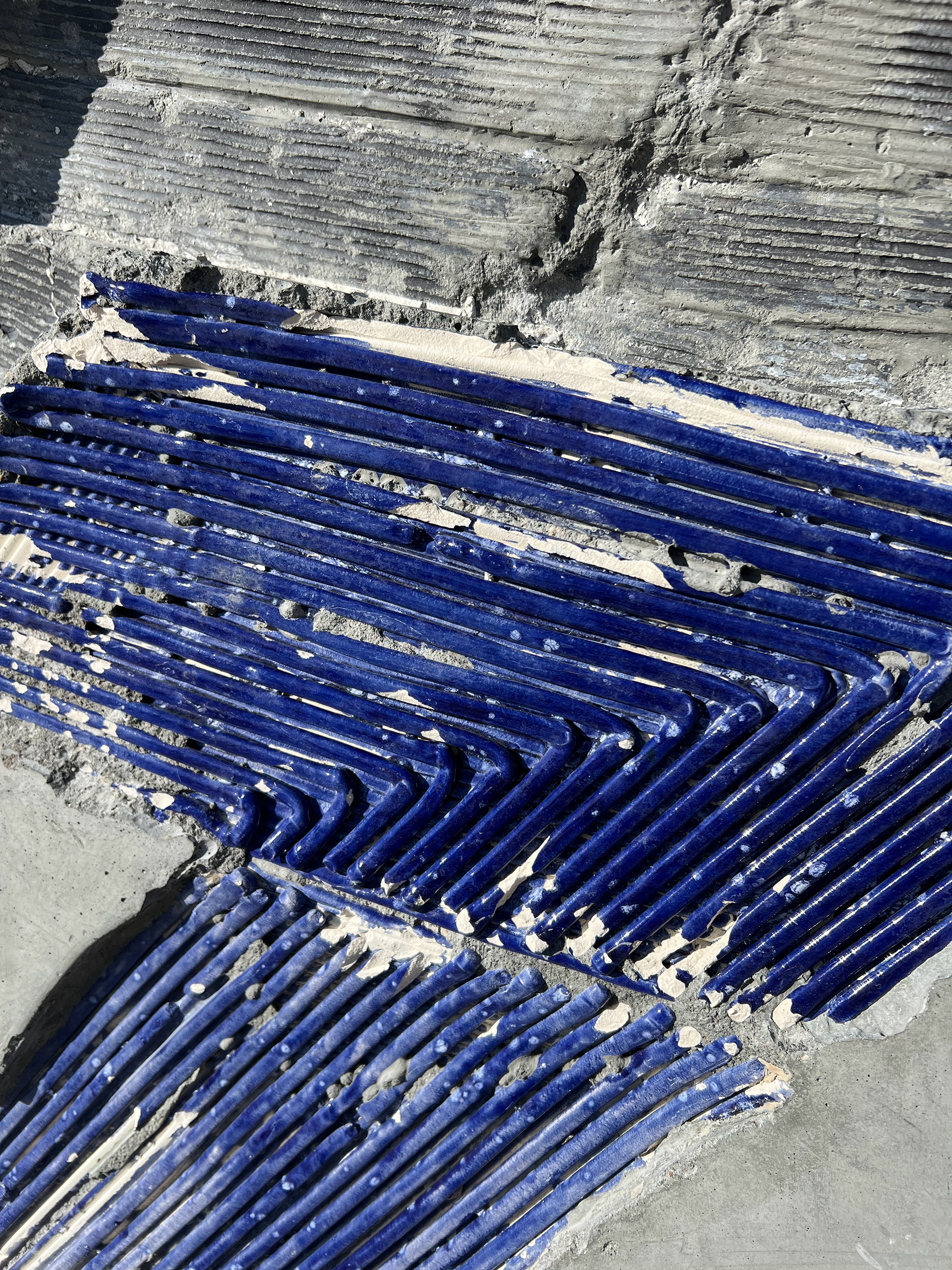

The fired clay pieces are meticulously 3D printed, forming intricate shapes that are designed to be detached from the concrete panel, creating a dynamic and tactile interaction between the materials. The glazed clay, finished in the distinctive AMACO Milky Way glaze, remains embedded within the concrete panel, offering a visually striking contrast between the raw, matte texture of the fired clay and the smooth, glossy finish of the glazed surfaces.

Institution: University of Pennsylvania

Programme: Robotics and Autonomous Systems

Programme: Robotics and Autonomous Systems

Model Director:

Richard Garber

Richard Garber

Teaching Assistant:

Drew Busmire

Project Team:

Carina Joseph

Wayne Chang

Qingyang Xu

Carina Joseph

Wayne Chang

Qingyang Xu

DESIGN LANGUAGE

The design draws inspiration from the museum’s diagonal façade pattern, though we have taken it further by introducing greater irregularity. Our pattern features a mix of materials and textures, with various bumps and intersections creating a more complex and dynamic composition, in contrast to the original, uniform design.

We employed a variety of materials to define the style of our panel. These include the smooth texture of the concrete, the rough surface of the foamboard, the striped patterns left by the 3D printed clay, and the rich blue finish of the glazed clay.

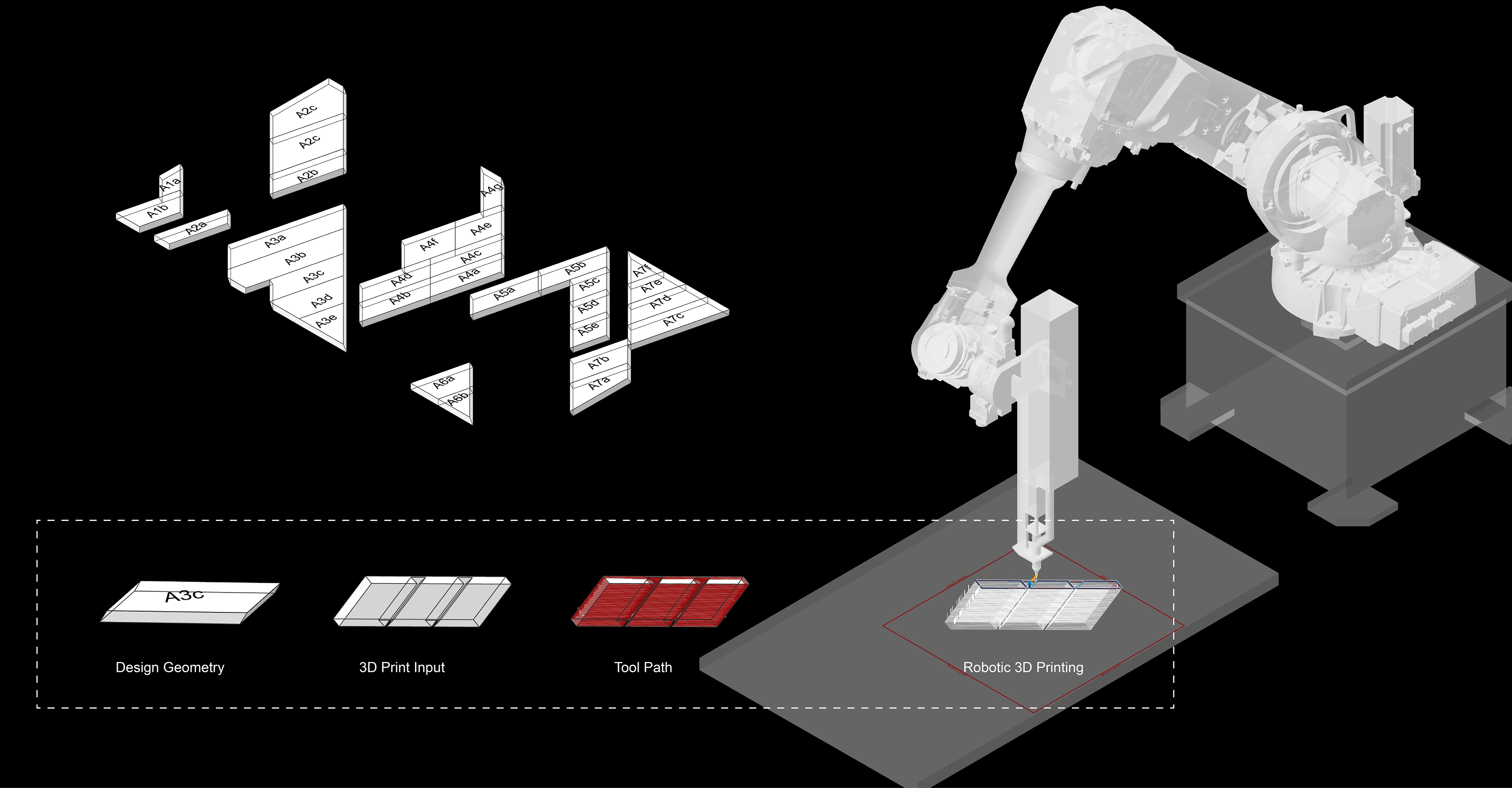

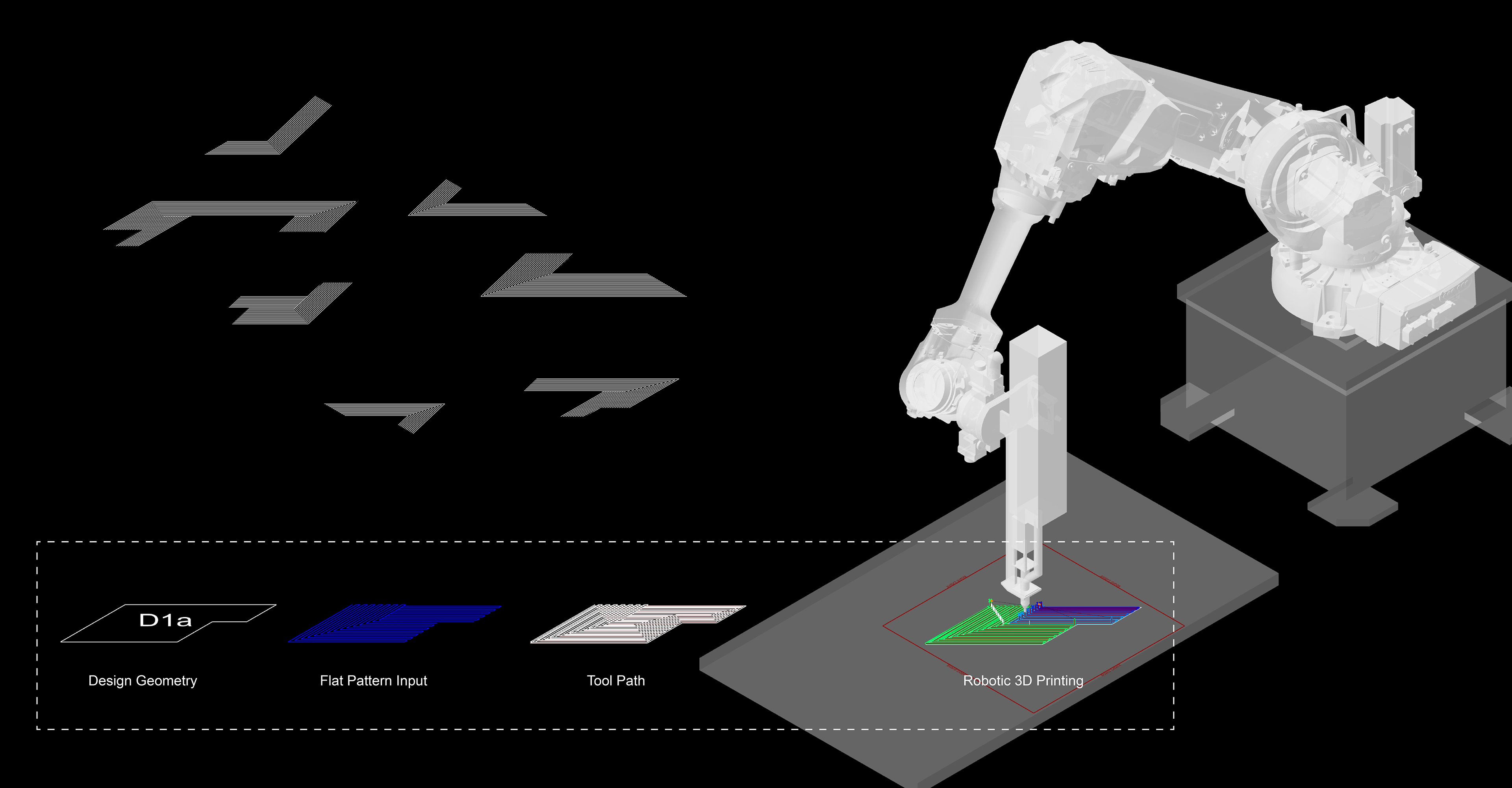

PRODUCTION PROCESS