MATERIAL: Wood

Drawing inspiration from the iconic Lodestar Tower in Canada, the project seeks to reimagine this landmark by creating a version of the original structure through the lens of wood joinery, rather than the metal braces used in the original.

Focusing on the inherent qualities of timber, the project applies a lignocentric approach, harnessing the material’s natural properties in combination with digital fabrication technologies. The core aim is to develop a version of the Lodestar Tower using a range of traditional wood joinery techniques such as tongue and groove, flap, finger, and dovetail joints; fabricated using robotic arms. The studio investigates the potential for robotic systems to precisely mill and assemble these complex joints, highlighting the precision and possibilities of modern woodcraft while considering ecological sustainability.

Institution: University of Pennsylvania

Programme: Robotics and Autonomous Systems

Programme: Robotics and Autonomous Systems

Model Director:

Alicia Nahmad Vazquez

Patrick Danahy

Alicia Nahmad Vazquez

Patrick Danahy

Teaching Assistant:

Mahsa Masalegoo

Jean -Nicola Dackiw

Soroush Garivani

Project Team:

David Chen

Huiyang Gong

Carina Joseph

To enhance both the structural performance and aesthetic appeal of the project, we establish a method for layering the timber components that optimizes material properties and leverages the natural strength and flexibility of wood. The layering process alternates between hard and soft timber, creating a dynamic system of material gradients that responds to both functional and environmental factors.

GEOMETRY GENERATION

The structure takes form by importing a closed brep into Grasshopper, which served as the starting point for the structure. By moving the point edges of the geometry, the brep was manipulated to produce a unique form.

JOINERY

STRUCTURAL ANALYSIS

The design was further optimized to ensure structural integrity, material efficiency, and aesthetic appeal. This step involved adjusting the parameters to achieve the desired balance between performance and form.

Based on the initial shape and transformation rules, structural elements like beams, trusses, and columns, will varying according to their thickness.

WOOD SELECTION

Ash

Douglas Fir

Maple

Walnut

From the neatly stacked rows of wooden boards, we had a range of woods in different lengths and thicknesses to choose from. For the prototype, the team decided on three hardwood species and one softwood species.

HARDWOOD (Ash, Maple, Walnut)

High durability and strength.

Strong and shock resistant.

Good for bending and shaping.

High durability and strength.

Strong and shock resistant.

Good for bending and shaping.

SOFTWOOD (Douglas Fir)

Vivid straight grains.

Strong and lightweight.

Affordable and readily available.

Vivid straight grains.

Strong and lightweight.

Affordable and readily available.

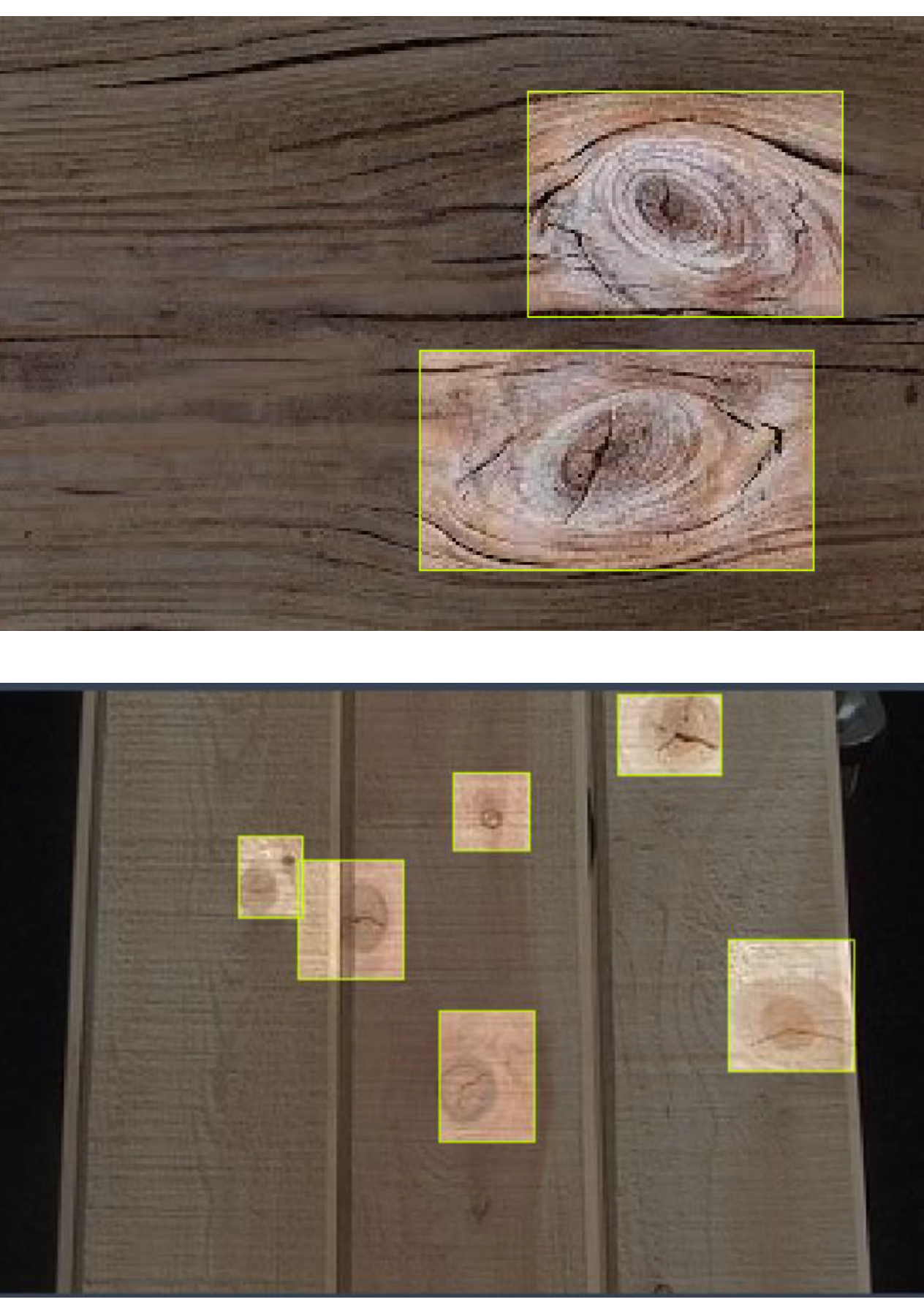

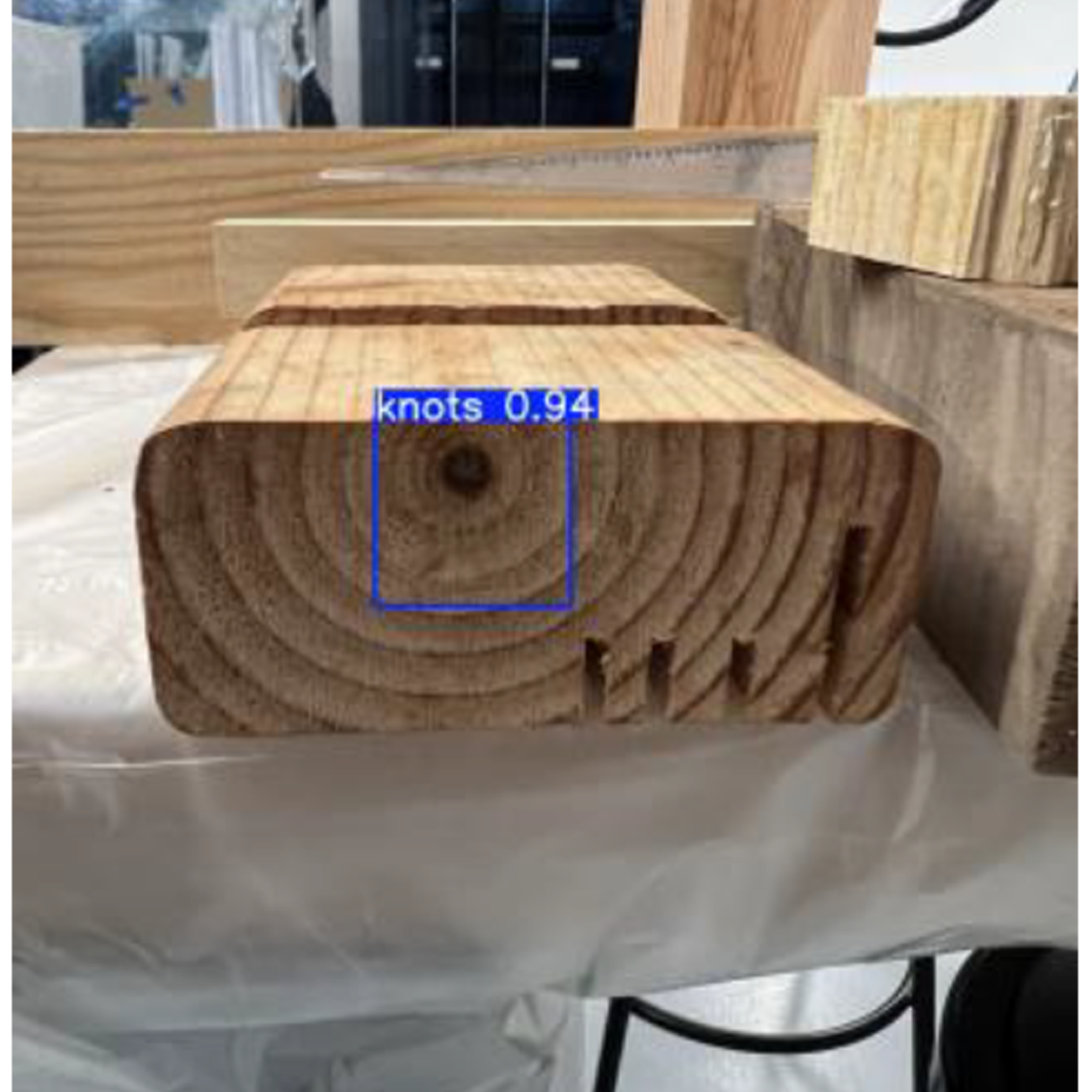

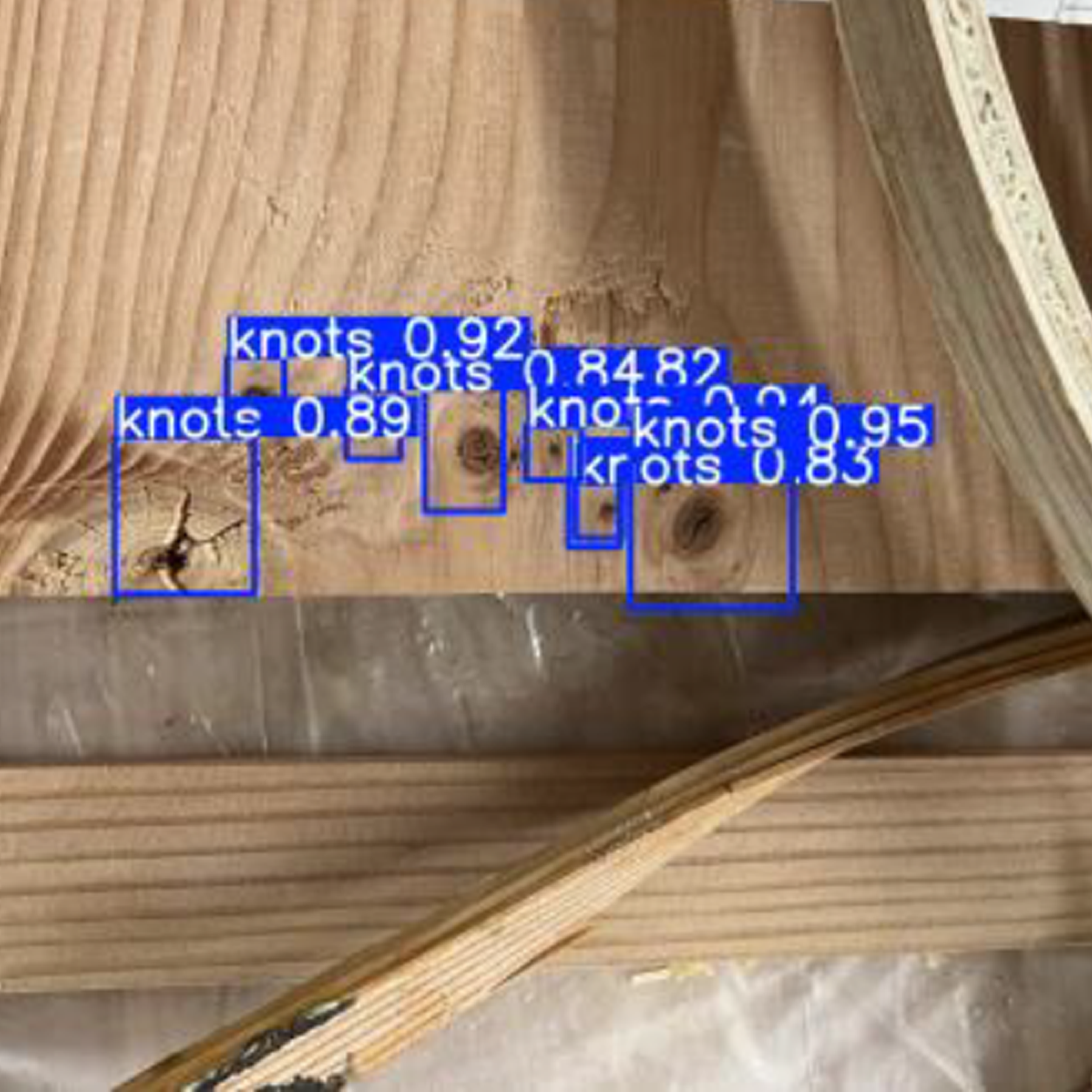

MATERIAL INSPECTION WITH MACHINE LEARNING

With the help of Machine learning tools, one can quickly identify imperfections crucial to the structures stability without the need to inspect manually.

This would predict the type and dimensions of the wood, suggesting preferable areas to be cut.

PREPARING PIECES

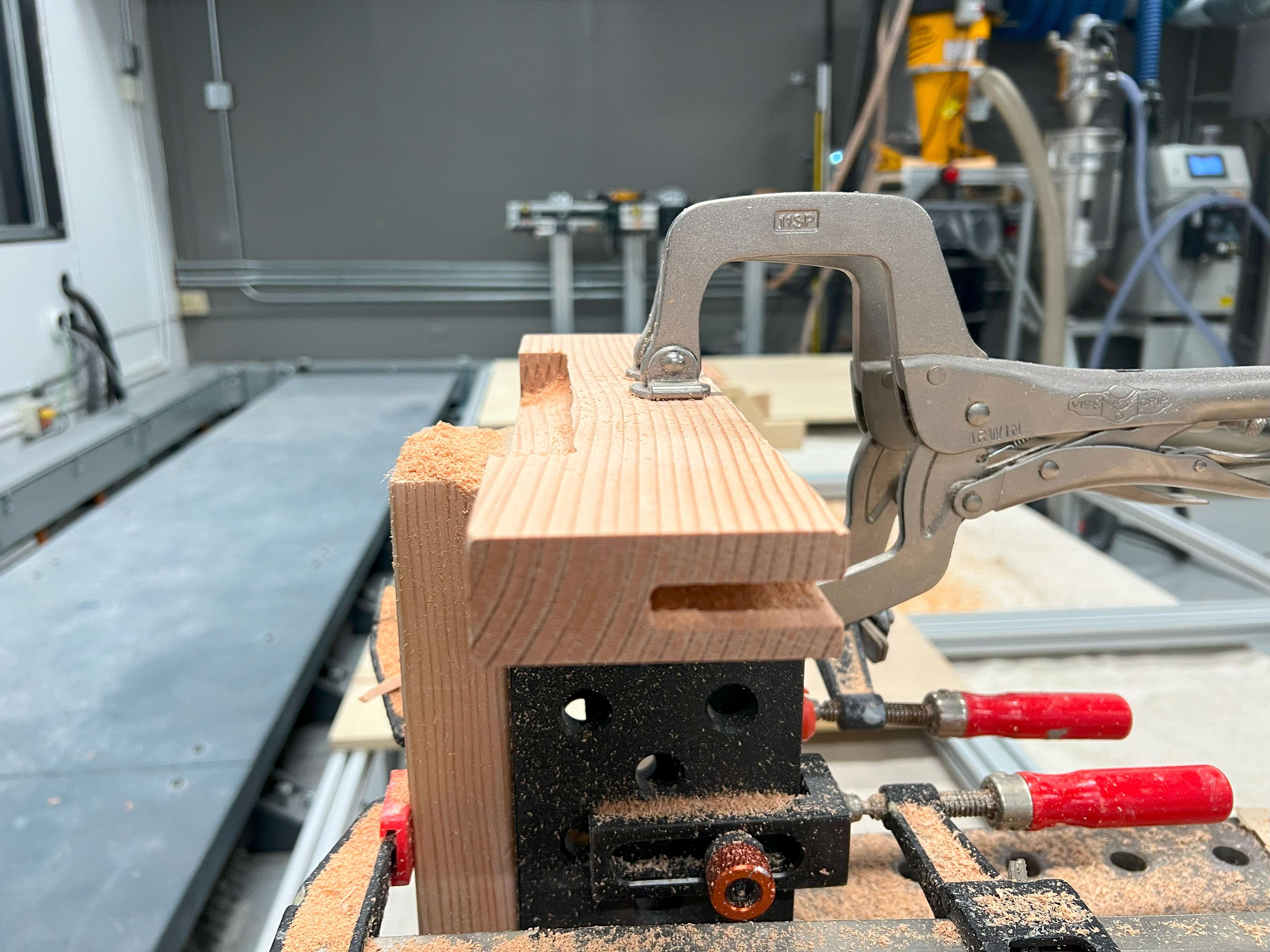

The preparation of wood strips for the laminated columns in the structural frame truss assembly involves several critical steps to ensure the strength, stability, and aesthetic quality of the final laminated beams.

The first step is to carefully inspect wood for any defects, such as knots or cracks. Thereafter, each piece of wood is cleaned to remove rough surfaces and any surface imperfections that could affect the adhesion during the lamination process using a jointer and planar machine.

Once the wood is clean and jointed, the material is cut into strips at specific lengths and widths.

The prepared wood strips are then arranged accordingly, and an appropriate adhesive is applied to its surface. The strips are stacked and held together with clamps until completely dry.

At this point, excess adhesive is cleaned off, and the surface of the columns is sanded smooth to achieve a uniform finish. The final laminated columns are then ready for milling to create each joint end.

Once the wood is clean and jointed, the material is cut into strips at specific lengths and widths.

The prepared wood strips are then arranged accordingly, and an appropriate adhesive is applied to its surface. The strips are stacked and held together with clamps until completely dry.

At this point, excess adhesive is cleaned off, and the surface of the columns is sanded smooth to achieve a uniform finish. The final laminated columns are then ready for milling to create each joint end.

COLUMNS AND BEAMS

CURVES